SERVICES

Analytical Services

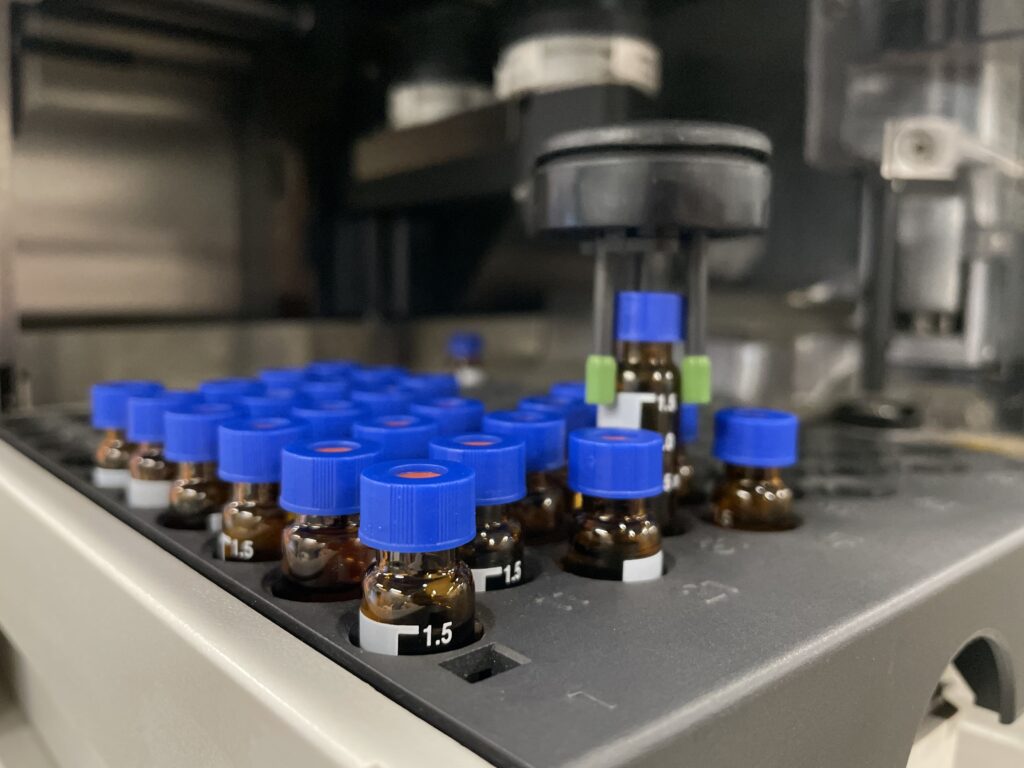

In-House Analytics | We source analytical equipment, install it in your lab, perform calibrations, provide complete SOPs, and handle routine maintenance.

- Cannabis and hemp processors commonly turn to in-house analytical testing (most commonly cannabinoid potency testing) in order to take advantage of long-term cost savings and rapid sample turnaround times. Some states in the U.S. are even banning compliance testing labs from offering “R&D testing”, forcing manufacturers to turn to in-house testing for quality control and R&D needs.

- To maximize cost savings, Seedless can remotely operate your instrument (HPLC), process data, and post results all via Wi-Fi, saving the need for a full-time chemist.

- Third-party compliance labs may take up to 3-5+ days to process samples, leaving manufacturing operations stagnant or otherwise interrupted until results are reported. With in-house analytical testing, sample results may be obtained within an hour or less.

- Short and long-term contracts negotiable (3, 6, 9+ months). Contract terms negotiable; services can be matched to the specific needs of the client.

Contractual R&D | A goal-oriented research project or series of experiments is completed on specified terms.

- A clearly defined research project or series of experiments is agreed upon. We perform the experiments, collect data, record our findings, and deliver a detailed lab report with transparent data. If requested, we will guide the client in interpretation of the data in the context of the project.

- Contract Seedless as a third-party laboratory to evaluate or validate manufacturing techniques, methods, and SOPs (yours or others).

Process Optimization | Optimize efficiencies of major processes and reduce wastes.

- Use chemical analysis (potency testing, etc.) to fine-tune each major step in your manufacturing process. Every percent counts in a competitive market.

- Reduce unnecessary processing waste to save money on hazardous waste costs and potentially lost product.

- Increase continuity of work flows. Design and/or adjust SOPs to be more ergonomic. Work should be designed to fit the operator, not vice versa.

Technical Services

Lab Design | Feel confident you are choosing the right equipment for your business plan. Make sure the lab layout and work flow is conducive to ergonomic operations.

- Be sure you are buying the right equipment for your production goals and the types of goods you are manufacturing. Don’t get stuck with inadequate or incorrect equipment.

- Choose a lab layout that maximizes production efficiency and avoids wasted energy.

- Get help with chemical safety requirements, such as storage/handling of hazardous materials, fire safety requirements, and more.

SOP Writing | We prepare standard operating procedures (SOPs) and other documentation, leaving you with more time for what’s important.

- Writing SOPs is a time consuming and tedious task. We can help satisfy regulatory requirements for SOPs, operational checklists, and other manufacturing record keeping and documentation.

On-site Consulting | We travel to your lab for in-person services: operator training, equipment installations, site evaluation, etc.

- Train operators to safely and effectively use manufacturing equipment (e.g., extraction systems, rotary evaporators, falling film units, distillation systems, etc.).

- Train technicians to perform many types of bench-chemistry techniques such as liquid/liquid extraction (i.e., ‘water washes’, ‘saline washes’), TLC (thin-layer chromatography), column chromatography (flash chromatography), and more.

- Install many types of manufacturing equipment: extraction systems (Delta Separations CUP series), filtration systems, falling film units, distillation systems, glass setups, etc.

- Perform site evaluations based on numerous aspects: work flow, process efficiency, operator ergonomics, cleanliness, health & safety concerns, or any other aspect of your lab.